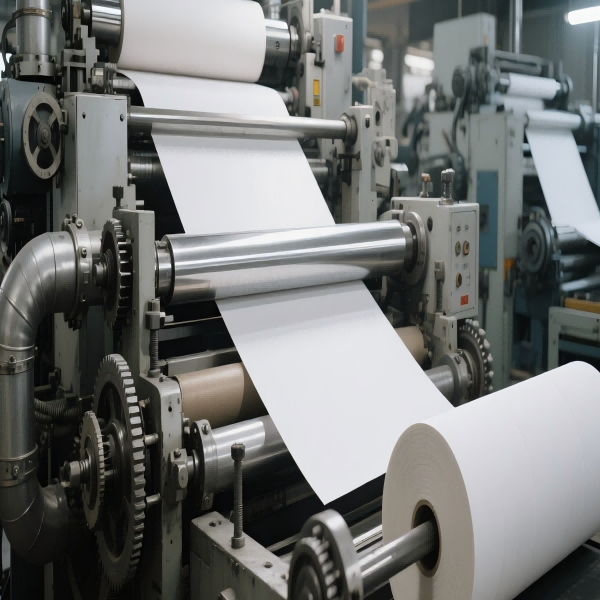

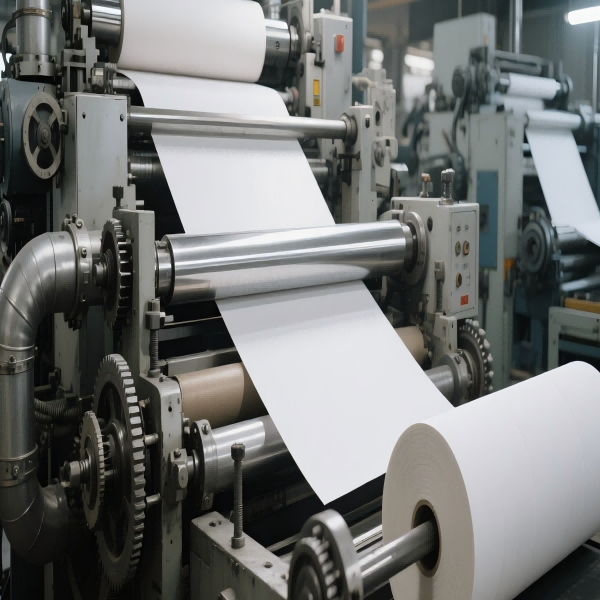

Premium Tissue Base Paper Jumbo Rolls — Trusted Supplier for Global Converters

Soft. Strong. Sustainable.

Get high-quality jumbo tissue base paper rolls for converting, packaging, and sanitary production lines — directly from a certified manufacturer.

Huaxinglobal Paper Jumbo Rolls

Huaxinglobal crafts high-quality tissue paper from sustainable wood pulp, ensuring softness, strength, and eco-friendliness. Our products include toilet paper jumbo rolls, facial tissues, napkins, and hand towels, ideal for commercial and personal use. Rigorous quality control and green sourcing guarantee reliable, absorbent, and durable solutions.

️ Technical Specifications

Our Premium Tissue Base Paper Jumbo Rolls are manufactured under strict quality control to ensure consistent softness, absorbency, and strength.

Each specification can be customized to match your converting line requirements — from GSM and roll width to core size and packaging type.

Parameter

Range / Options

Description

Remarks / Customization

GSM (Grammage)

13 – 45 gsm

Determines softness and strength level

Custom GSM available for toilet, facial, or kitchen use

Roll Width

1000 – 3600 mm

Suitable for different converting machine widths

Can be slit to required sizes

Pulp Type

100% Virgin Wood Pulp

Affects brightness, softness, and cost

FSC-certified virgin pulp optional

Moisture Content

4% – 6%

Controls flexibility and smoothness

Monitored per batch for stability

Brightness (ISO)

80% – 88%

Higher brightness for premium tissues

Adjustable based on pulp ratio

Core Size

3” / 6”

Standard converting roll cores

Other sizes upon request

Packaging

Kraft paper + PE film

Moisture-proof and export-ready

Palletized for sea/air shipment

Key Highlights

Our Premium Tissue Base Paper Jumbo Rolls are engineered for toilet tissue, facial tissue, kitchen towel, and napkin converting lines.

100% Virgin Pulp

Ensures softness, absorbency, and strength

Direct Factory Supply

Competitive price, stable quality

Custom GSM & Roll Width

Flexible specs for converting machines

Global Export Service

Fast shipping to 30+ countries

Core Paper Jumbo Roll Products

Industry Applications Scenarios

Our Premium Tissue Base Paper Jumbo Rolls are the foundation for a wide range of converting and production applications.

Whether you produce toilet rolls, facial tissue, napkins, or kitchen towels, our jumbo rolls deliver the softness, absorbency, and strength your customers expect — consistently, batch after batch.

Toilet Tissue Converting Lines

Provides smooth texture and high tensile strength — perfect for household and commercial toilet rolls.

Kitchen Towels & Household Rolls

Excellent absorbency and durability, maintaining structure even when wet.

Industrial Cleaning & Hospitality Use

Used in hotels, hospitals, and cleaning sectors for bulk supply and hygienic performance.

Facial Tissue & Napkin Production

Soft, lint-free, and ideal for skin contact products such as pocket tissues and boxed facial tissues.

Why Choose Jumbo Rolls Over Smaller Reels?

Choosing large jumbo tissue rolls gives you stronger productivity, better cost control, and consistent quality — especially for high-speed converting lines.

Higher Efficiency

Large jumbo rolls reduce downtime by minimizing reel changes on the production line.

Lower Cost per Meter

Bulk rolls save on core, packaging, and logistics costs.

Consistent Quality

Uniform GSM and moisture control ensure even converting performance.

Eco-Friendly Production

Fewer roll cores and less packaging waste — better sustainability.

Global Raw Material Partner

Connect with Huaxinglobal for premium tissue paper raw materials and end-to-end converting solutions. Our ISO 9001-certified facility supplies FSC-certified jumbo rolls, parent rolls, and customized substrates for napkins, facial tissues, and towels. Request samples or discuss OEM projects via:

Phone

+86-13599169075

Tissue Paper FAQs

-

Q1:What are parent rolls?

A1: Parent rolls (also called mother rolls or jumbo rolls) are large-diameter base paper rolls directly from paper machines. Ranging from 1-3 meters wide and weighing 1-5 tons, they serve as raw material rolls for converting into finished tissue products.

-

Q2:How are toilet rolls cut?

A2: In 3 stages:

Log sawing: Parent rolls are slit into narrow "logs" using high-speed rotary knives

Embossing/Perforating: Patterns applied via steel rollers

Cutting: Logs sliced into individual rolls with laser-guided blades (±0.1mm precision)

-

Q3:What is the conversion process?

A3:Key stages:

① Unwinding: Jumbo roll mounted on automated unwind stand

② Ply bonding: Multi-layer laminating (if applicable)

③ Embossing: Pattern imprinting for thickness/softness

④ Log processing: Slitting → Cutting → Core inserting

⑤ Packaging: Automated shrink-wrapping or flow-wrap systems

-

Q4:Do parent rolls vary in size?

A4: Yes. Standard specs:

• Diameter: 1.2m - 1.8m

• Width: 1.5m - 3.2m

• Basis weight: 13-50 gsm

Custom sizes available for specialized converting machines, with MOQ from 5 tons.

-

Q5: What are key production stages?

A5: 1: Pulping: Virgin/recycled fiber processing

2: Paper forming: Fourdrinier wire section

3: Drying: Yankee dryer at 120-150°C

4: Creping: Doctor blade scraping for softness

5: Reeling: Forming jumbo rolls

6: Converting: Slitting/embossing/cutting

7: QC: ISO 9001-certified testing

-

Q6: What’s the difference between virgin and recycled tissue base paper?

A6: 100% Virgin pulp offers higher softness and brightness, while recycled pulp is cost-effective and eco-friendly.

-

Q7: Can you customize GSM and width?

A7: Yes, we can tailor roll width, GSM, and packaging based on your converting machine specifications.

Related Blogs

-

Tissue paper is essential in daily life, from homes to businesses. Have you ever wondered how it all starts? It begins with the creation of Tissue Paper Mother Rolls, the foundation for products like toilet paper, napkins, and paper towels. In this article, we’ll dive into the process behind Tissue Paper Mother Roll production. You'll learn about the equipment, production stages, and ways to improve efficiency through automation and modern technology.

Tissue paper is essential in daily life, from homes to businesses. Have you ever wondered how it all starts? It begins with the creation of Tissue Paper Mother Rolls, the foundation for products like toilet paper, napkins, and paper towels. In this article, we’ll dive into the process behind Tissue Paper Mother Roll production. You'll learn about the equipment, production stages, and ways to improve efficiency through automation and modern technology. -

The global paper industry is on a rapid growth trajectory, impacting sectors like packaging, hygiene, and commercial printing. As the industry adapts to increasing consumer demand for sustainable materials, it’s expected to reach USD 351.7 billion by 2025. In this article, we’ll explore key statistics and growth projections for the paper market heading into 2026. You'll discover how trends like eco-friendly production methods and automation are reshaping the industry and what it means for businesses.

The global paper industry is on a rapid growth trajectory, impacting sectors like packaging, hygiene, and commercial printing. As the industry adapts to increasing consumer demand for sustainable materials, it’s expected to reach USD 351.7 billion by 2025. In this article, we’ll explore key statistics and growth projections for the paper market heading into 2026. You'll discover how trends like eco-friendly production methods and automation are reshaping the industry and what it means for businesses. -

Have you ever wondered how a simple roll of paper could make or break your production line? The right paper tissue mother reel is more crucial than you think. In this article, we’ll show you how to choose the ideal paper tissue mother reel for your equipment. You'll discover how small details like GSM, diameter, and material can transform your production efficiency and product quality.

Have you ever wondered how a simple roll of paper could make or break your production line? The right paper tissue mother reel is more crucial than you think. In this article, we’ll show you how to choose the ideal paper tissue mother reel for your equipment. You'll discover how small details like GSM, diameter, and material can transform your production efficiency and product quality. -

Did you know that everyday tissue products can contribute to deforestation? As consumers demand more eco-friendly options, it’s essential to understand the impact of the materials used. In this article, we will explore what makes virgin wood pulp tissue rolls eco-friendly. You’ll learn how sustainable sourcing, minimal chemical use, and responsible production methods help reduce the environmental footprint of these essential products.

Did you know that everyday tissue products can contribute to deforestation? As consumers demand more eco-friendly options, it’s essential to understand the impact of the materials used. In this article, we will explore what makes virgin wood pulp tissue rolls eco-friendly. You’ll learn how sustainable sourcing, minimal chemical use, and responsible production methods help reduce the environmental footprint of these essential products. -

Have you ever wondered how tissue products can be made softer, stronger, and more absorbent while also being more environmentally friendly? Through Air Drying (TAD) technology is revolutionizing the tissue manufacturing industry by doing just that. Unlike traditional methods, TAD uses high-velocity air to dry tissue sheets, enhancing product quality and reducing energy consumption. In this article, we’ll dive into how TAD works, its key benefits, and how companies like Huaxin Global are using this innovative technology to lead the way in sustainability and high-quality production. Get ready to learn how TAD is transforming the tissue industry for the better!

Have you ever wondered how tissue products can be made softer, stronger, and more absorbent while also being more environmentally friendly? Through Air Drying (TAD) technology is revolutionizing the tissue manufacturing industry by doing just that. Unlike traditional methods, TAD uses high-velocity air to dry tissue sheets, enhancing product quality and reducing energy consumption. In this article, we’ll dive into how TAD works, its key benefits, and how companies like Huaxin Global are using this innovative technology to lead the way in sustainability and high-quality production. Get ready to learn how TAD is transforming the tissue industry for the better! -

Ever wondered how jumbo rolls of paper become the soft toilet paper in your bathroom? The process behind Toilet Paper Roll Converting is more fascinating than you might think. In this article, we dive into the secrets of the Toilet Paper Roll Converting process. Discover how raw materials, advanced machines, and cutting-edge innovations come together to create the toilet paper we rely on every day.

Ever wondered how jumbo rolls of paper become the soft toilet paper in your bathroom? The process behind Toilet Paper Roll Converting is more fascinating than you might think. In this article, we dive into the secrets of the Toilet Paper Roll Converting process. Discover how raw materials, advanced machines, and cutting-edge innovations come together to create the toilet paper we rely on every day.